Our services are dynamic and versatile. We are experienced in carrying out works in fabrication yards, refineries with stringent safety regulations, cramped conditions with limited mobility such as inside ships and FPSOs, confined spaces as well as at heights of 30m and more.

Surface preparation is the essential first stage treatment of a substrate before the application of any coating. The performance of a coating is significantly influenced by its ability to adhere properly to the substrate material.By far the most significant and important method used for the thorough cleaning of mill-scaled and rusted surfaces is abrasive blast cleaning. This method involves mechanical cleaning by the continuous impact of abrasive particles at high velocities on to the steel surface to achieve the required specification set by Client and in accordance to relevant ISO/AMPP standards.

We have performed various blasting operations using aluminium oxide, garnet, steel grit & shot, copper slag and other abrasives in various sizes. Throughout our years of service, our operations were 100% efficient in the removal of mill scale and rust.

Thermal Spray Application Technology is widely recognised & preferred method across many industries that Improves or restores the surface of a solid material. This process can be used to apply coating to a wide range of materials and components in diverse climate conditions with no curing period, greater hardness, superior adhesion and provide resistance to abrasion, corrosion, cavitation, erosion, heat or wear by extending the coating life of an average of 30 years which is superior to conventional coatings with a proven performance history.

Thermal Spray Application are adopted In controlling Corrosion in various Industries like the Marine, Oil & Gas Industries, Land Transport. Ports, Wharfs. and many more.

The corrosion in the Structural Steel works. Marine Environments. Oil & Gas Industry is a particularly important issue. Low carbon steel is commonly used as a structural material for marine applications, despite its relatively poor corrosion resistance. Due to the high chloride levels present in marine environments, coupled with erosion and microbial effects, extensive material loss occurs in offshore platforms, pipelines, and ships. It has been estimated that the cost of corrosion is high along with environmental damage. In industrial environment such as in freshwater, marine environment, under thermal insulation or hot surface area, thermal spray aluminium is the most chose due to its superior performance_ Aluminium is an outstanding material found as the most effective for steel protection. Aluminium performance can withstand either in acidic or alkaline condition. Aluminium coating advantages come from its ability to form passive film formation & sacrificial protection, thus giving a lower corrosion rote. Aluminium also offers less weight and cheap price compared to zinc. One of the key factor aluminium is more preferable because of its high temperature resistance_ This coating system is effective for Immersion, splash-zone, and atmospheric services. This coating offers a tough barrier coating. it is economical, it provides effective protection for refinery and process plant vessels, tanks and steel fabrications. against corrosion under insulation with less maintenance-free service.

Transport infrastructure truly adds speed, efficiency and economy growth to a country's progress. Land transport infrastructures are composed of fixed installations for canals, highways, railways, roads and terminals. These infrastructures in such corrosive environments naturally poses constant threats of damage from atmospheric conditions, rood debris, density of traffic, as well as increased emission. Unfortunately, the maintenance cost against corrosion for these platforms are very high. To combat this inevitable challenge, Thermal Spray Aluminium coaling can be applied for structures built with stainless steel & Thermal Spray Zinc which can be applied directly in concretes and replaces galvanized coating used in bridges, MRT Lanes & barriers. These coatings are offering excellent resistance against corrosion and at minimum maintenance cost to improve friction and wear, its results enhance the life span of materials and machine parts, simultaneously reducing efforts on maintenance or repair work.

In the UK, Forth Road Bridge is coated with Thermal Spray, while at Hurst Green Railways, the footbridge is coated with Thermal Spray Zinc.

Ports are the central link between maritime and land transportation, serving as a central gateway for exports and imports that contribute to the prosperity of a nation, The concrete and steel structures in such sea-busy environments inherently require high costs for maintenance due to regular removal of corrosion products, sea-fouling and scale, and periodical painting as well. Pipelines and tanks at ports and wharfs also commonly experience pitted corrosions that reduces the strength and hardness of steel. Thermal Spray Aluminium is then aptly used to increase its thickness at pitted areas - which solidifies and strengthens the steel over lime_ Used for centuries as a protective coating, cathodic protection, Zebra Mussel protection and for cavitation damages in maritime environments such as ports, wharfs, bridges and other components, Thermal Spray Application demonstrates excellent results against corrosion & coating protection without the risk of heal distortion on components & also in concrete and steel structures.

In Japan, Thermal Spray Zinc Aluminium is applied to the Columns of a Floating Deck, Kanda Port (1990), and Thermal Spray Aluminium Is used for Seaside Bridge, Kagoshima Pod (1997), Ash Marine has been actively involved in the application of thermal spray coatings on various industries throughout the region utilizing metals such as Zinc, Aluminium, Nickel Zinc Aluminium Alloys (85/15), Stainless Steel and other alloys lo provide long-term corrosion protection over conventional coatings. We have slate of the art Arc Spray and Flame Spray machines along with highly trained and experienced personnel.

Ash Marine is proudly one of the leading companies in the region for protective coating applications. Ash Marine has performance various blasting using aluminum oxide, garnet, steel grit & shot, copper slag and other abrasives in various sizes in accordance to clients’ requirements.

Ash Marine has the latest blasting pots, vacuum recovery machines, vacuum blast machines, spray pumps and other equipment. Our large range of sophisticated modern equipment’s and highly skilled personnel enables us to take on large projects and be able to complete them within the stipulated time without compromising quality or safety.

ASH Marine is recognized as an industry leader in independent coatings technology and inspection services. We have certified under AMPP “Standard Procedure".

Ash Marine’s paint inspection experience includes work on all types of structural steel, tanks, ships, bridges, pipelines, oil fields, chemical plants, and nuclear facilities

Delivering cost effective non-slip solutions just about any floor surface that routinely gets wet, oily and slippery, offering a high-traction surface. The safety that a non-skid floor provides is well worth the investment of time and money. Creating a durable non-skid floor will provide peace of mind and reduced liability from slips and falls.

Ashmarine has delivered to corporations and major government organisations that demand only the best in quality and fast-turnaround after-sales service that reduce your downtime.

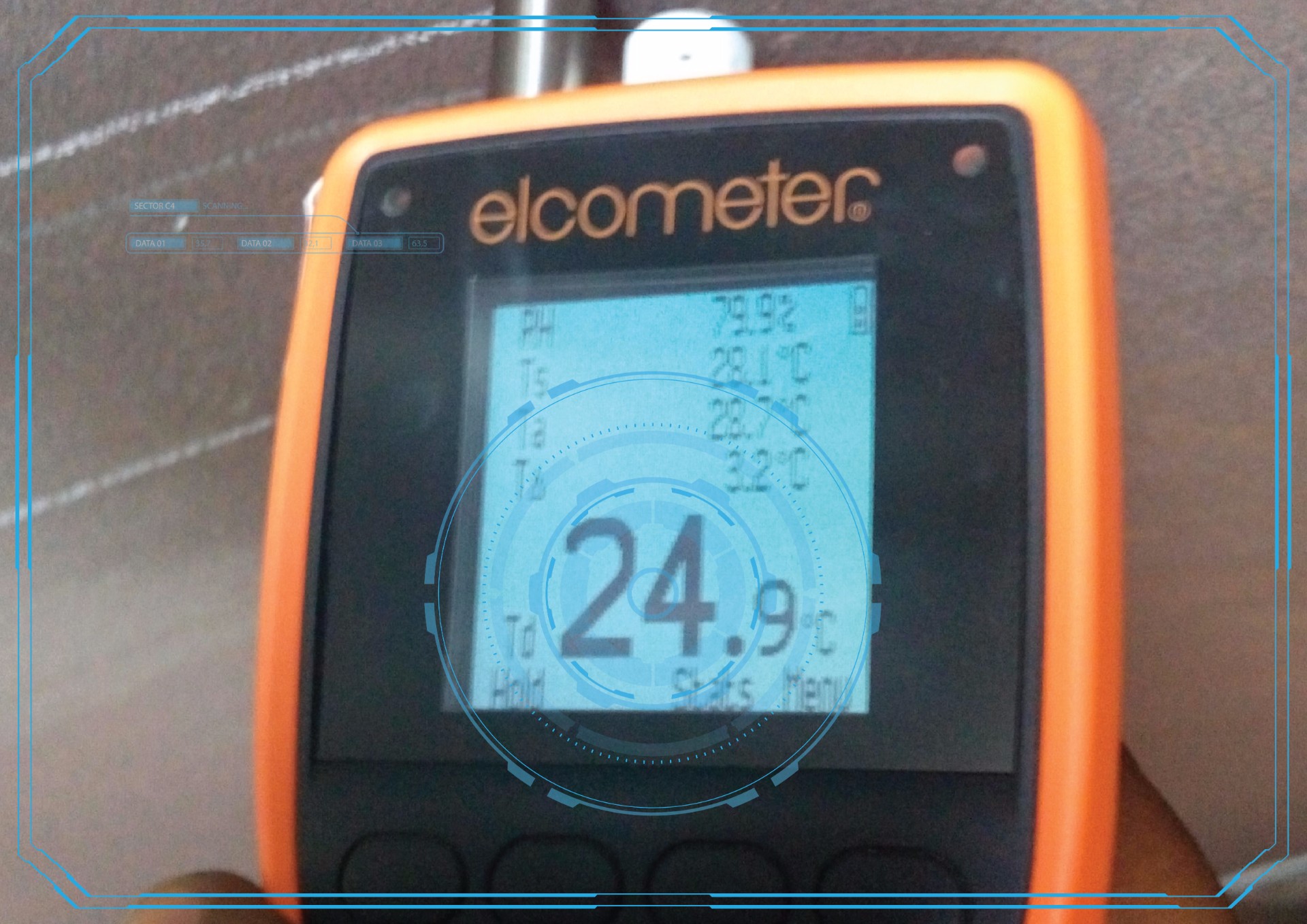

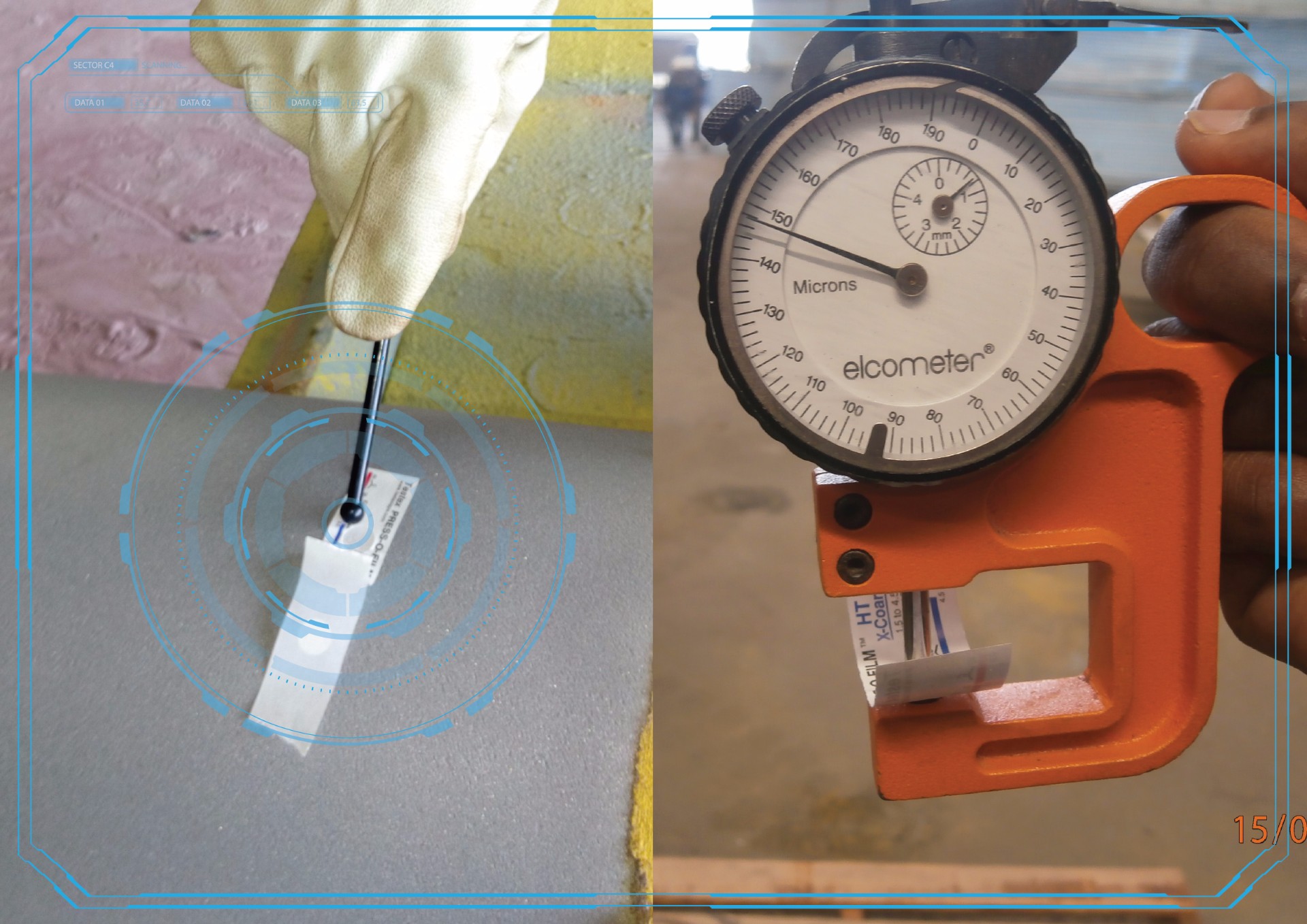

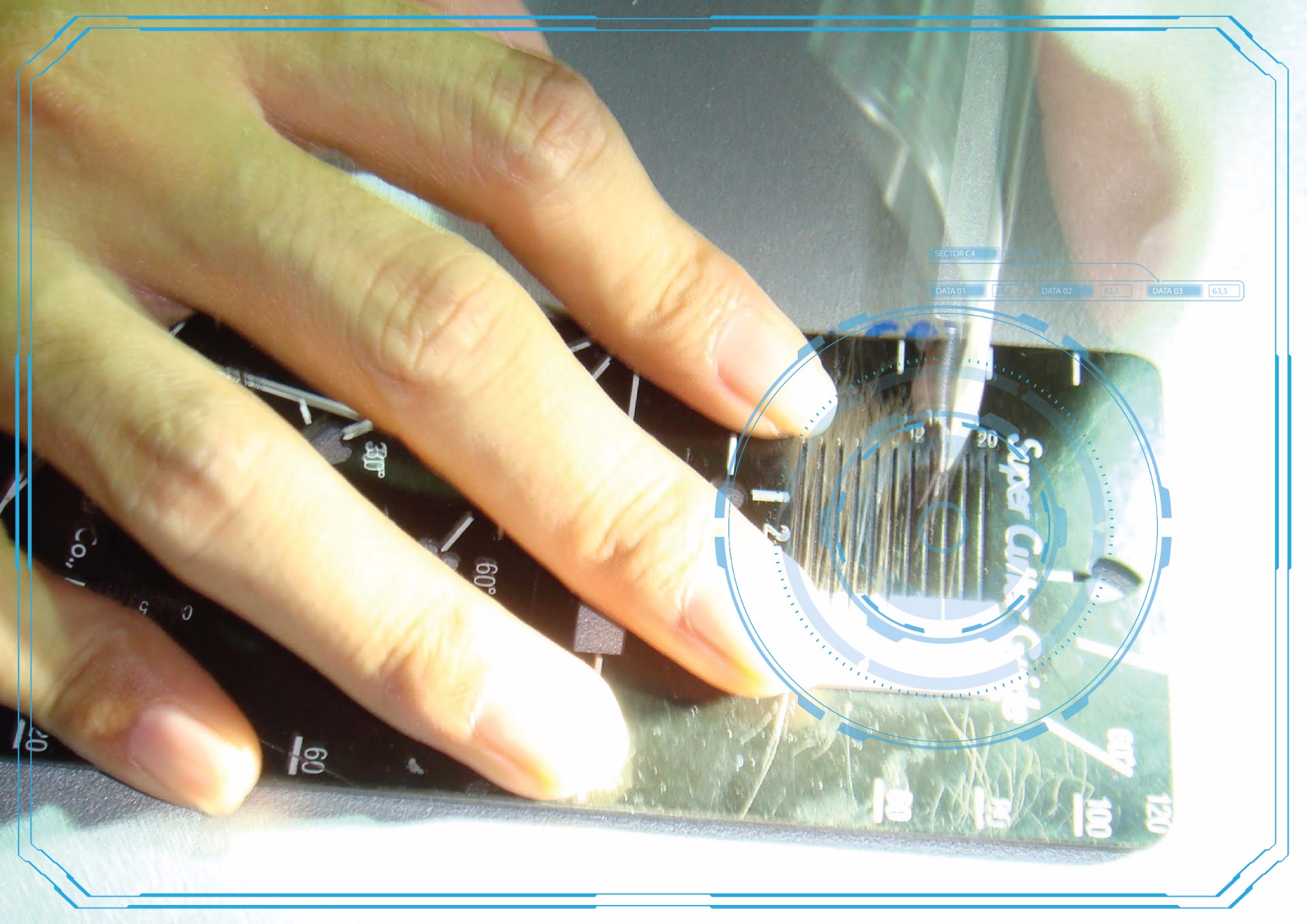

Coating inspection services help owners of industrial and commercial structures mitigate the risks of corrosion by verifying the quality and longevity of protective coating systems. Verification of coatings application quality is highly desirable when structures of any type are undergoing repair or replacement of exterior coatings or interior linings. Our services on behalf of facility owners provide verification that the practices are adequate to achieve the desired final product as defined in the painting specification.

Ash Marine has highly trained, experienced and NACA & SSPC certified professional Protective Coatings Inspection Inspector inspectors. Our unparalleled paint inspection experience includes work on all types of structural steel, tanks, ships, bridges, pipelines, oil fields, chemical plants and nuclear facilities, as well as commercial properties and buildings.